#AC-DC Rectifier

Explore tagged Tumblr posts

Text

AC-DC Rectifier: Bridging Two Worlds of Power

Imagine a world without electricity conversions — where your laptop won’t charge, your phone stays dead, and industrial motors fail to operate. Unthinkable, right? What stands between AC power from the grid and your DC-powered electronics is an essential, often invisible device: the AC-DC Rectifier.

Despite being critical to everything from daily gadgets to complex aerospace systems, the rectifier rarely gets credit for the massive transformation it enables. Let’s change that.

From Alternating to Direct – Why It Matters

Alternating Current (AC) is how electricity travels through our power grids. It’s efficient for long-distance transmission, easy to step up or down in voltage, and suitable for large-scale energy distribution. However, most electronics — your smartphone, LED lights, electric vehicles, and even high-end servers — run on Direct Current (DC).

So how do we bridge this gap?

Enter the AC-DC Rectifier, the vital converter that transforms grid-fed AC into usable DC. It’s not just about electricity; it’s about adaptation — evolving the flow of energy to meet the needs of technology. And in that transformation lies an intricate blend of science, design, and application.

A Story You Can Relate To

Meet Priya, an electrical engineer at a solar microgrid company in Rajasthan. Her challenge wasn’t lack of solar energy; it was inconsistent performance from stored power. The culprit? Cheap, inefficient rectifiers that distorted the signal and degraded batteries.

When Priya introduced industrial-grade AC-DC Rectifier modules with controlled ripple and thermal protection, battery life improved by 30%, and the system uptime went up dramatically. What seemed like a simple switch turned out to be a major performance boost — something her team hadn't fully anticipated until they saw it in action.

The rectifier wasn’t just a component anymore — it was an enabler.

The Tech Under the Hood

So how exactly does an AC-DC Rectifier work?

At its core, rectification involves converting a sinusoidal AC wave into a linear DC line. This is achieved through the use of diodes, thyristors, or MOSFETs, depending on complexity and application.

1. Half-Wave Rectification

Only the positive half of the AC signal is allowed to pass through. It’s simple, but inefficient and used only in low-demand circuits.

2. Full-Wave Rectification

Both halves of the AC waveform are utilized. With the help of bridge rectifiers, the output is more consistent, ideal for higher-power applications.

3. Controlled Rectifiers

These use semiconductor devices like SCRs or IGBTs, allowing engineers to control output voltage levels — essential for motor speed controllers and battery chargers.

4. Filtered Rectifiers

To reduce “ripple” — the leftover wave-like behavior in DC — capacitors and inductors are added to smooth out the flow.

Each rectifier type serves different needs, from tiny phone chargers to complex power supplies in industrial automation.

Why It Matters More Than Ever

The rise of DC-based technologies makes AC-DC Rectifier systems even more critical today than they were a decade ago.

1. Electric Vehicles (EVs)

Charging stations rely heavily on rectifiers to ensure batteries receive pure, stable DC. A poor rectifier can shorten battery life and reduce driving range.

2. Renewable Energy

Solar panels generate DC, but many systems need AC to interface with the grid — and vice versa. Modern energy systems use rectifiers to maintain voltage stability.

3. Data Centers

Servers operate on DC. Rectifiers convert incoming AC to keep massive infrastructure running smoothly — a split-second glitch can cause thousands in downtime.

4. Medical Devices

Precision instruments like MRI machines or ventilators require pure, distortion-free DC. This level of quality is only possible through specialized rectifiers.

Humanizing the Current

Let’s not reduce this technology to circuits and silicon. The AC-DC Rectifier is a guardian of stability. When you’re working late on a presentation, your laptop humming reliably — thank the rectifier. When hospitals maintain life-support systems during a blackout with the help of inverters and UPS systems — thank the rectifier. When satellites silently collect data while orbiting Earth — again, thank the rectifier.

It doesn’t just convert voltage; it converts possibilities into realities.

The New Era of Smart Rectifiers

Thanks to advancements in power electronics, today’s rectifiers are smarter, more efficient, and application-specific.

Wide Bandgap Semiconductors (SiC, GaN): They allow for faster switching, higher temperatures, and smaller components. Great for high-frequency and aerospace applications.

Digital Control Systems: Feedback-based systems help monitor current, correct fluctuations, and adjust to real-time demand.

Energy Recovery: Some modern rectifiers are designed to push unused energy back into the grid or battery systems.

Modular Rectifier Systems: Ideal for scaling power supplies. Need more output? Just plug in another rectifier module.

Tips When Choosing an AC-DC Rectifier

Whether you're an engineer, project manager, or someone setting up a high-powered system, here’s what to consider:

Power Rating: Match it to your load requirements.

Input Voltage Range: Ensure flexibility for different global standards.

Efficiency (>90%): Better efficiency means less heat and lower power bills.

Thermal Management: Good rectifiers come with built-in cooling or heat sink options.

Certifications: UL, CE, or ISO depending on the region and industry.

EMI Filtering: Reduces interference in sensitive systems.

Redundancy Features: In mission-critical applications like healthcare or aviation, dual rectifiers with automatic failover are a must.

Final Thoughts: More Than a Converter

The next time you plug in a charger, boot up a server, or admire an EV silently gliding past, remember — an AC-DC Rectifier is working behind the scenes. It's the bridge between chaotic currents and calm, directed energy. It's not just about volts and amps; it's about reliability, precision, and trust.

If you're building or maintaining systems where power matters — give the rectifier its due importance. Because in a world that runs on conversions, AC-DC Rectifier technology is the unsung foundation of modern energy infrastructure.

0 notes

Note

tell me everything about AC to DC filters Right Now

:0

Dear god.

OK I have to make some assumptions or else this is going to get really long. I am going to assume that you already know what AC and DC are. I am going to assume that you took (and passed) geometry, so a sine wave and it's variations are familiar to you. I am also going to assume that you also know the difference between voltage, current, and resistance.

So, what are AC to DC, why do we care about that? Well, the electricity coming out of the wall is AC, but in order to, lets say, charge your laptop battery, you need DC. In fact, if you look at a laptop charger, you'll see The Brick. The thick rectangle that gets hot when charging the laptop.

THAT'S THE AC TO DC CONVERTER

I just called it converter instead of filter. Why? Because filters technically only remove a 'ripple' from DC current, so a current that's almost DC but not quite. If you are making the entire jump from AC to DC, then that's called a converter.

Now here's where things get fucked.

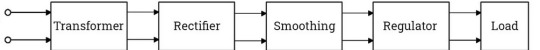

These are all of the parts after the plug. The load is your laptop, the regulator is your filter.

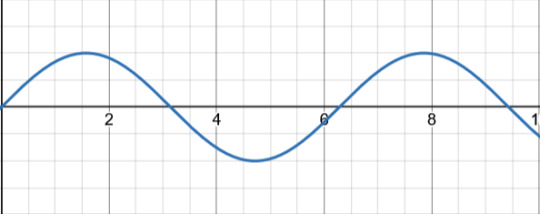

Let's say that this is your AC signal (this graph showing the voltage over time). Now, the first thing this passes through is the transformer, which only adjusts the voltage to the correct level. Some devices need it higher, some lower. Let's say that this transformer is a step up transformer, because it made the signal bigger.

The next step is the rectifier. Now, traditionally this part is taught in stages in order to show it's affect on the signal. I'm going to speed run that. I will assume that you're familiar with what a diode is. If you aren't, just know that it only allows current to flow in one direction. So, anything going backwards will be removed. Picture a one way valve.

So, if we were to send this signal through one diode, then that would leave us with

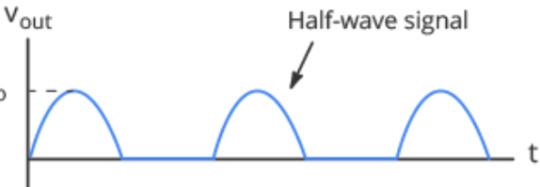

just the positive half! That's why this setup is called a Half-wave rectifier.

But what if we were to use two diodes. As in, fill in the blank spot that the negative half left with another positive bump. That would give us

This lovely thing! Which is great, but it requires another AC signal that is 180 degrees off from the original one in order to exist. Which, transformers exist which can provide that, but it's not cost effective. So, that leaves us with the most common setup, the Bridge Rectifier.

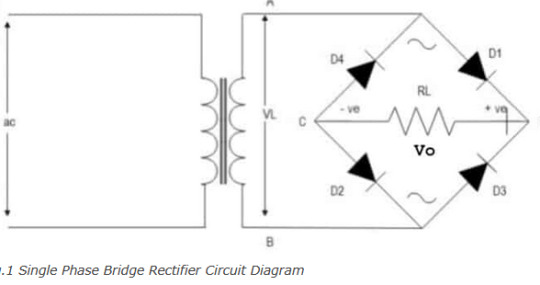

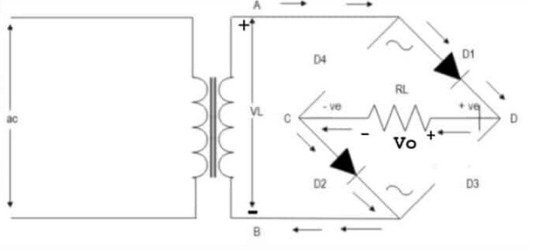

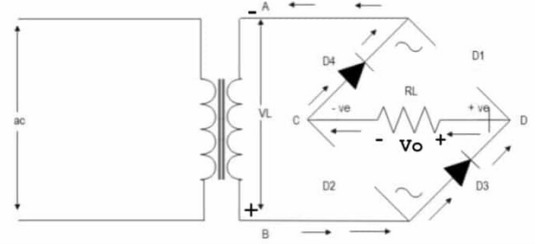

I've been skipping the circuit diagram so far, but now it's important.

THIS thing is a bridge rectifier connected to the transformer (yes that's what transformers look like according to circuit diagram shorthand). Now, I am American, and for some reason American electricians use that up and down sharp thing in the middle of the diamond to indicate a resistor. Europe uses a rectangle. Again, I am going to assume that you know what a resistor does.

Those four black triangles with lines? Those are diodes. The line across the tip of the triangle indicates what direction they are allowing current to flow into. Now picture you were a positive signal flowing in through point A into the bridge. There's a split in the circuit, but one way (diode D4) is blocked, so you have to go across diode D1. Now you're at the edge of the diamond, once again two ways you can go. You head towards diode D2, because diode D3 won't let you through. What that looks like is this

What about the other direction? Well that looks like

Notice that the edges of the diamond are called out? Points C and D. That's the money makers. You see, if you plug into point D as your positive and C as your negative, you get a full wave signal! (so sorry for not going fully in depth on why that works just trust me it's a bit of a mess and should really be taught with the actual circuit in front of you, not across the internet like this)

A full wave signal is completely positive, but it's not exactly DC yet. That's where smoothing comes in. This is done with a capacitor!

The capacitor is charged up and then slowly releases it's charge. But before it can completely discharge, it gets recharged by the next wave. Quick review, a capacitor is like a battery where it can be charged up, but unlike a battery which holds charge with chemistry, capacitors hold charge with physics. They can still wear out, but not nearly as quickly as a battery.

What does that red line look like? Well, almost like a straight line, except it has RIPPLES! That's right, we're finally back to the filter! Or the regulator as the diagram calls it. Means the same thing.

Sometimes, this step is skipped. If the device getting signal isn't too sensitive or it's just cheep, then the electricity stays bouncy. Some devices really care about any fluxuation in the signal, in which case they get a big expensive filter.

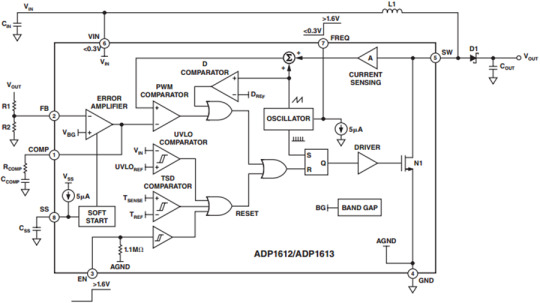

Unfortunately, the inner bits of a filter are many, so I won't be going into all of that. But you want me to go into that, so I will show a circuit diagram.

This is a diagram of the ADP1612

This website has a downloadable version of the spec sheet!

But that's a level of detail that you usually only get into if you are planning on building a circuit. The day that you're flipping through spec sheets in order to check compatibility is when you've really become an engineer.

So that's how you go from AC into DC. Yes, I just spent an hour typing this all out. I like electricity a lot.

Here's a GREAT video that goes over all of this but the guy actually has a circuit and an ossiliscope in front of him to show the signal.

#electricity#electronic#electrical engineers#physics#AC to DC rectifier#electrical engineering#mmm electricity for power#ask#literally several college classes worth of info that I am skipping in this#ough my circuit bits#I chose the perfect degree I am built for this shit

11 notes

·

View notes

Text

0 notes

Text

https://www.futureelectronics.com/p/semiconductors--discretes--diodes--standard-rectifiers/1n4148wtq-7-diodes-incorporated-4041450

Diodes, Standard Rectifiers, 1N4148WTQ-7, Diodes Incorporated

1N4148WT Series 2 A 80 V 150 mW Surface Mount Fast Switching Diode - SOD-523

#Diodes#Standard Rectifiers#1N4148WTQ-7#Diodes Incorporated#what is a rectifier#AC to DC Converters#chip#circuit#Standard Recovery Power Rectifier#bridge rectifier#Half Wave Controlled Rectifier#Diode rectifier circuits

1 note

·

View note

Text

The SNCF CC 40100 (and its Nez Cassé relatives)

Thought I’d do an info/context post on these engines since a lot of the fandom doesn’t seem to know much about them. It’s more or less implied canon that this is the engine Electra is, his replica helmet is based on SNCF 40104 specifically, complete with number plate. Further down I also go into how I like to incorporate/interpret some of the history of these engines with the character.

For those of you totally new to trains: SNCF is the French nationalized rail system. The CC 40100 came out in the mid-late 60s as the first of the Nez Cassé line of locomotives, probably the most iconic French trains until the TGVs. They were a line of express passenger/fast freight locomotives that came out between the 60s and early 90s that all had a distinct “broken” front silhouette that looks very 80s despite being first designed more than two decades before Stex came out.

The CC 40100 was a funky, relatively experimental model designed to take four different voltages so it could travel over most of western Europe on the new, high-end Trans Europ Express services. In both the northeast US and much of Europe, electrification was done piecemeal over several decades by different companies/nations, resulting in a patchwork of AC and DC lines running different voltages and/or frequencies, as well as both third rail and overhead wire. Dual voltage electric engines have existed since the turn of the century, but demand for triple and even quadruple-voltage electric trains didn’t develop in Europe until the rise of the EU and border-crossing trains like the TEE that would otherwise need an engine change or use diesel power to run on multiple countries’ systems and standards. There were a number of triple and quadruple-voltage engines and MUs developed in the 60s for this purpose, but the CC 40100 was notably stronger than many of them, to work heavier trains and due to anticipated use on mountainous lines in Switzerland.

Technologically, the CC 40100 had DC traction motors, technological limits restricted the use of AC ones until the 80s-90s. They ran at 1500 V DC, could also take 3000 V DC by changing motor connections, and had transformer and rectifier equipment for taking two voltages and frequencies of AC power. Unusually, they had four pantographs, many multi-voltage engines were built to work on third rail lines and a more common setup was one or two pantographs and a “shoe” collector for third rail. They also never ended up using their fourth 15kV 16 2/3 Hz AC voltage for German/Swiss running in regular service and it’s a little hard to find out why, I’ve heard both technical concerns with equipment getting hot or political factors.

It made the CC 40100 relatively complicated, unreliable, and expensive to run (and the weight of the equipment is why it had six axles in a Co-Co arrangement vs the more common four—axle Bo-Bo setup). There were some interesting features like a gas-filled vs oil-filled transformer to save weight, and corrugated stainless steel body panels like American Budd railcars. They never got used to their full potential for various political/practical reasons and the quad-voltage capability became a delicate overkill, so only ten were made. TEE also fell out of relevance into the 80s as business travelers moved to planes and the market for first-class trains declined. They had a more limited use and service life than other Nez Cassé engines as a result, though 25-35 years is still a decent run and comparable to other TEE multi-voltage engines of the era. As a fun bonus, one was restored and runs excursions today (40110) and there’s lots of video on youtube! Apparently the group that runs it also has a steam engine and I can’t help but wonder how maintenance compares.

youtube

Canon Electra accurately reflects a number of traits of these engines (though I take issue with them being picked as a representative of electric traction because they’re pretty specialized and atypical). AC and DC are both okay by them, they almost exclusively ran first-class TEE services, and were prone to overheating and catching fire. Not exploding though, THAT’S almost purely the domain of steam engines. Bidding the Nationals farewell in “No Comeback” in their various languages and not having a clear country of origin also tie in well to the 40100’s intended use as a pan-European engine. As a very fun cultural link, the Kraftwerk song “Trans Europ Express” mentions David Bowie and I can’t help but wonder if that’s why they chose this engine as a basis for Electra. The song definitely has a similar vibe to the character, though the CC 40100s never ran the exact route mentioned in the song, since they never ran in Germany in general. As an even more fun cultural link that was probably unintended, this song and Kraftwerk in general were really popular in early hip hop and techno circles…. which also checks out to the direction Electra took in the actual production.

From the illustrious sources of reddit and translated youtube comments, French railfans really like these engines, even if a lot of the Anglophone internet thinks they look weird. They have a status akin to the Concorde as a symbol of attempted European collaboration and unity. They could also be compared to a more modern Santa Fe Super Chief, in terms of being a flashy luxury train that was popular in model/toy form. The Nez Cassé classes in general seem to have an E/F-unit esque “iconic colorful, glamorous old engine strongly associated with a specific country” reputation on general. “The TGV is numerically better but these are SHINIER” is a common sentiment. They were physically loud in service between the motor whine and loud cooling fans, there’s some good cab ride footage on youtube where you can hear it. “Diva Electra” is a lot closer to their reputation than the eerie lifeless zombie of the workshop. There are/were eerily silent electric engines, but those with DC motors rarely were, they brake with giant resistors that get hot like a space heater or toaster and need loud, powerful cooling fans.

So ironically, Electra’s “face” is an engine more akin to an electric, European equivalent of Greaseball culturally. Actually very dated technologically, if anything most of their problems were because they were designed well before computers. Hardly threatening and if anything more seen as a symbol of optimism and progress. Which ends up reflecting a lot when it’s demonized by media from a country with infamously limited electrification progress vs mainland Europe (the more I learn about British train politics then and now the more I can’t take Stex at face value).

OTHER NEZ CASSÉ CLASSES

These videos give a great overview (in French but have English subs)

Co-Co (larger) models:

youtube

Bo-Bo (smaller) models:

youtube

First of all, if you ever want a cheap idea for an Electra recolor OC, there was a Belgian equivalent to the CC 40100 that looks just like that. These ones actually ran services in Germany!

I’ve joked about it before but there was also a very successful diesel Nez Cassé, the CC 72000, which is basically the French equivalent of Greaseball. Big (by European standards) mixed traffic fast freight/passenger engine that lasted about 50 years, covering the increasingly few non-electrified lines in France.

There were also a bunch of more typical 1-3 voltage electric Nez Casse types built for use in France and a number of other countries (Portugal, the Netherlands, Slovenia, Korea… and some failed systems in Morocco and Brazil). Most of these worked notably well and ran for 30+ years, quite a number still run today in Slovenia, Portugal, and on some low-end French trains that haven’t been replaced by EMUs. I would broadly describe them as very typical European-style mixed traffic engines capable of passenger or faster freight services, their role is comparable to something like a Siemens Eurosprinter or Bombardier TRAXX today. Ironically NOT a dedicated high speed train power car and a relatively antiquated but durable and versatile style. Locomotive-hauled trains have become increasingly uncommon in Europe in favor of EMUs with the decline in rail freight, among other factors. People seem to really like the old loco-hauled French trains still running since they use really comfortable older coaches and are pretty cheap, lower-speed options.

I’m prone to swapping Electra’s basis a bit to the related CC 6500 and its variants because it opens a lot of interesting history and is a more “typical” electric engine. These were a beefier, more versatile first-gen Nez Cassé model also used on pre-TGV fast trains and later heavier freight trains. There’s some amusing youtube videos of them pulling big gritty tanker trains with their pretty flashy looks. They also weren’t used as long as the later smaller Bo-Bo electric models since they’re a bit overkill for most uses, EMUs have gradually taken over passenger services, freight services declined, and the Co-Co arrangement can be tougher on track. Their freight-oriented close relatives in Slovenia are still going though!

But they have the VERY interesting link of one (X996) being trialled by Amtrak in the late 70s as a replacement for the 40+ year old GG1s that were physically falling apart, and the freight-derived GE E60s that couldn’t manage the speeds required on the Northeast Corridor. Sources seem to vary on just how hopeless and ill-advised the endeavor was, but basically, X996 didn’t work well due to the terrible track condition of the Northeast Corridor vs typical French lines. To summarize a very deep-seated and messy issue: it was cobbled together from several 50+ year old, often poorly maintained mainlines and has been underinvested in since until VERY recently. They went with the X995 instead, a Swedish Rc model that worked a lot better since Swedish rail conditions are generally closer to the US. And also a design that dated back to the mid-60s. The AEM-7s based on them ran until the late 2010s, the last one actually got retired right around the time Electra got de-toothpasted in 2018

This alternate timeline aspect is what got me into Amtrak history and eventually American electrification in general. I doubt any of the creators were aware of X996, but the context behind a Nez Cassé style engine running in a vaguely US environment changes a lot. It implies an alternate timeline where the NEC was improved enough for it to actually work practically and opens the door for some tragically attainable sci-fi about “what if neoliberalism hadn’t taken over and the US invested in a passable passenger rail system?”. It makes me imagine nearly 50-year old funny nosed French trains running grimy fast freight trains in Pennsylvania or dragging on New Jersey Transit commuter trains in their twilight years. It feels weirdly natural with just how violently 70s they look with the Amtrak livery, they’d blend right in with how violently 70s many US trains look today, that’s how old they actually are.

It’s also where my more unhinged and sacrilegious opinions flipping the steam/electric dynamic and rejecting canon’s framing came from. Because it totally flips the circumstances of rail transport and gives a cohesive explanation for many“stupid and incorrect” aspects of Electra. Now Electra is more a business-class train at best, running on a notoriously run down and underfunded network in an era where electrification looked like it would finally expand but never did (due to the party and politics of “needn’t ask the world to turn around and help you”). No Comeback goes from a shitty tantrum to pretty tragic in light of the US resoundingly turning to fossil fuels in the 80s and even steam preservation doing better than electrification did then. And in the context of a country that’s 99% unelectrified that was running electric trains from the 30s and even as old as the 1910s… suddenly a 60s-70s era engine is actually pretty futuristic and being electric is an important selling point and being proud and defensive of it makes sense. Electra skewing Grace Jones at times even works out well because being unappreciated and running off to Europe fits the rejection of X996 and expanding electrification in general. I think early Amtrak is a compelling setting for the show in general since there was a chaotic mix of secondhand equipment and trials of foreign engines to explain the races, and basically every character could feasibly coexist besides Rusty (and my fundamental problems with him are their own even longer post).

Electra as a more “typical” Co-Co Nez Cassé is also why I gravitate towards a lot headcanons/preferences that are far removed from the original or typical character choices. Tall and thin? The Northeast Corridor has fairly low clearances, it makes sense to be medium-short, modernish electric engines usually aren’t that big anyways, especially compared to other US rolling stock. X996 would be a bit smaller and comparable speed-wise but actually stronger than Greaseball. Internal combustion was still fairly competitive with electric traction speed-wise in the 70s-80s, you still had attempts at high-speed turbine trains and the TGV had originally been planned as one pre-oil crisis. Ironically, the big advantage pure electric engines had (and still have) IS strength and power (especially per weight) because they don’t have to carry their own fuel source and massive electric motors were established long before effective high-horsepower rail diesel engines were. I really can’t overstate how weirdly impressive it is that Mykal is the most train-accurate Electra and I love that he ends up being a lot of people’s first exposure to the character due to being in almost all the English legal video. The hotter/bolder personality vs being delicate and anxious. The jarring mix of being a glamorous diva train but ridiculously beefy physically is so dead-on to how French people describe the 6500s and Co-Co models in general. Even being unusually old and increasingly visually beat up while slapping a coat of glittery paint on it is so dead on to struggling passenger networks running sometimes absurdly old trains and putting on a sparkly veneer to improve PR.

Anyways, this has been an exploration of the irl engines behind Electra and their often underappreciated yet widespread significance. This also explains a lot of the method behind my madness and contrarianism with this character. Go forth and make an army of funny nose French trains in any color and country you want. Seriously, this style was so widespread and generally beloved you can justify them almost anywhere and even some of the old diesel units are getting moved to secondary markets today.

#stex#starlight express#stex electra#reference#if you want more explanation on something or are more acquainted with these engines and have a correction let me know#info on them can be a little tricky to find in english and i was delighted that those subbed videos even exist#Youtube

30 notes

·

View notes

Note

I saw your addition on the melting metal post, i was wondering how A/C electricity works, and how the energy transfers, is it like a newton’s cradle?

The short answer is that power is transferred in an AC circuit not by redistributing electrons from point A to point B, but by the electromagnetic fields produced by the movement of electrons in general. An electron moving back and forth still produces those fields due to its motion, even if "on average" it doesn't go anywhere.

To be a little more precise, current is defined as the charge crossing through a cross-sectional area per second. If an electron moves forward and backwards through that cross section, there is charge flowing through it, and so there are electronic fields being produced that a device can harness to do things. Many devices (for instance, an incandescent light bulb) don't particularly care if the fields change direction, so long as they exist. For devices that do care about the changing amplitude or direction of the current, we convert AC to DC using a rectifier.

In an intuitive sense, you can think of it kind of like a hand saw. The saw just moves back and forth, so it's not going anywhere "on average". But the cutting is produced by the movement of the saw blade against the material, so it cuts as long as there's movement in either direction.

#this is again something I'm admittedly not as familiar with as one might expect of an electrical engineer#A bit of googling went into this answer#my work focused more on the materials themselves rather that a circuit as a whole#or even individual devices like a diode or transistor#so take my answer with a grain of salt

7 notes

·

View notes

Text

Terex 33-19 "Titan", Sparwood (No. 3)

Terex put the Titan into service with Kaiser Steel at its iron mine at Eagle Mountain, California, in January 1975. The Titan experienced frequent downtime, but hauled approximately 3.5 million tons of earth over the course of its four years of service at the Eagle Mountain mine.

In late 1978, the Titan was sent to Kaiser Steel's mine at Sparwood, British Columbia, Canada. The mine was acquired from Kaiser Steel by B.C. Resources in 1980. When the mine was subsequently acquired by Westar Mining in 1983, the Titan was repainted from its original Terex lime green livery to Westar Mining's blue and yellow livery. Shortly after, Westar Mining purchased the Titan from General Motors for US$200,000 ($610,000 today) and $1 million of spare parts ($3 million today). During Westar Mining's ownership, the Titan had an uptime rate of more than 70% and regularly hauled loads exceeding 350 short tons (320 t). Westar Mining retired the Titan from service in 1991.

The Titan has a payload capacity of 350 short tons (320 t), a net vehicle weight of 509,500 pounds (231,100 kg) and a gross vehicle weight of 1,209,500 pounds (548,600 kg). Fully loaded, the Titan had a top speed of 29.8 mph (48.0 km/h). At the time of its construction in 1973, the Titan was the largest, highest payload capacity truck ever built. The Titan remained the highest capacity haul truck in existence for 25 years until the début of the 360-short-ton (330 t) payload capacity Caterpillar 797 in September 1998.

The Titan used a diesel/AC electric powertrain that consisted of an Electro-Motive Division model 16-645E4, 16-cylinder, gross 3,300 hp (2,461 kW), 10,320-cubic-inch (169.1 L), turbocharged, intercooled, unit injection, locomotive engine directly coupled to an Electro-Motive Division model AR10-D14, 10-pole, AC electric alternator sending DC power via a rectifier to General Motors model D79CF traction motors at each of the four paired rear wheels. The Titan utilized a power, all-wheel steering system. The front wheels swept through a 71-degree arc. At a preset point as the front wheels moved off-center, the eight rear wheels would also begin to steer, moving up to a maximum of 10 degrees off center. The Titan required ten 40.00x57 tires.

Source: Wikipedia

#Coal Miner by Nathan Scott#Sparwood Miner memorial statue#World's Largest Tandem Axle Truck#Terex Titan#Terex 33-19 “Titan”#Sparwood#travel#original photography#vacation#tourist attraction#landmark#cityscape#architecture#landscape#countryside#summer 2024#Canada#technology#engineering#Terex green livery#big truck#roadside attraction#free admission#British Columbia

3 notes

·

View notes

Text

Can we use a 24V headlight on a 240V AC?

No, you cannot safely use a 24V headlight directly on a 240V AC power supply, and attempting to do so would likely result in immediate failure of the headlight or even dangerous hazards like fire or electrical shock. Here’s why:

1. Voltage Mismatch

Headlight Rating: Most automotive headlights are designed for 12V or 24V DC systems (direct current), common in cars, trucks, or motorcycles.

240V AC Risk: A 240V AC power source (alternating current) delivers 10 times the voltage the headlight is rated for. This would cause: • Instant Overload: The filament or LED circuitry would burn out due to excessive current. • Insulation Failure: Wiring insulation might melt, creating a fire hazard.

2. Current Type Difference

AC vs. DC: Headlights are engineered for DC power, while household 240V is AC. Even if voltage were matched, AC can damage DC components (e.g., LEDs or ballasts in HID lights).

3. Safe Workarounds (If Absolutely Necessary) To use a 24V headlight on 240V AC, you’d need:

Step-Down Transformer: Reduces 240V AC to 24V AC.

Rectifier Circuit: Converts AC to DC (since headlights require DC).

Voltage Stabilizer: Ensures stable 24V DC output.

Example Setup:

Transformer: 240V AC → 24V AC (e.g., a 24V, 100W transformer).

Rectifier: Converts 24V AC to ~34V DC (peak), then use a voltage regulator to stabilize at 24V DC.

Fuse Protection: Add a fuse to prevent overload.

Cost: $20–$50 for components, but not recommended unless you have electrical expertise.

4. Better Alternatives

Use a 240V AC Bulb: Buy a bulb rated for 240V AC (common in household or industrial lighting).

24V DC Power Supply: Use a dedicated 24V DC power source (e.g., batteries or a lab-grade DC supply).

Key Risks

Fire Hazard: Overheating from incorrect voltage/current.

Component Failure: Burnt-out filament, melted wiring, or exploded LED drivers.

Safety Violations: Tampering with AC mains power may violate electrical codes.

Bottom Line Do not connect a 24V automotive headlight directly to 240V AC. Instead, use a properly rated bulb or a 24V DC power system. If you need bright 240V lighting, opt for AC-compatible LED or halogen bulbs designed for household/industrial use.

#led lights#car lights#led car light#youtube#led headlights#led auto light#led light#led headlight bulbs#ledlighting#young artist#car culture#cars#cartoon#self care#race cars#sabrina carpenter#carlos sainz#classic cars#suv#porsche#truck#supercar#carte postale#automobile#car#headlight bulb#headlamp#headlamps#headlight#aftermarket new lamp

2 notes

·

View notes

Text

Auntie Splitfoot

“witch” © Vladimir Matyukhin, accessed at his ArtStation here

[It will probably surprise none of you that I am a big fan of hags as villains, having written multiple original species of them. Despite this, every time I’ve used a hag in my games, it’s been as a one-and-done thing rather than as a recurring villain. Auntie Splitfoot is my attempt to rectify this situation with a character who both has reasons to let PCs live if they cross paths early in an adventuring career, and who can escape a losing fight by going ethereal.]

Auntie Splitfoot CR 11 NE Aberration This woman has greenish-gray skin and a leering expression. Her hands are claws and her mouth is oversized and filled with sharp teeth. Saw-toothed fronds like the leaves of a plant grow from her scalp instead of hair, and below the waist she has a mass of ribbon-shaped tentacles instead of legs.

Auntie Splitfoot is a dealer in the soul trade, and she values her ability to work with a wide variety of customers and to broker deals between them. She trades equally with all manner of evil outsiders, and even has some qlippoth clientele. The qlippoths typically just want to destroy the souls she sells them, but that doesn’t matter to her. She recently upgraded her own body, allowing herself to be mutated as payment from Doctor Agatha Shiny. Auntie Splitfoot’s sobriquet used to refer to her hoofed feet, and she is delighted that the mutagens used appropriately shredded her legs into tentacles.

Auntie Splitfoot carries a bow to deal with the odd golem and to torment foes from afar, but she much prefers to get close to combat and fight with her teeth and claws. She is remarkably durable, and if she is injured, will typically shift herself into the Ethereal Plane for a few rounds to heal up before resuming battle. Although she is sadistic, she is pragmatic first and foremost, and would rather flee a losing fight, or pay a token bribe, then fight to the death. Anyone who fights Auntie Splitfoot and lets her live, however, will likely deal with nightmares and other retribution as punishment for their victory.

The reason Splitfoot goes by “Auntie” has to do with her primary hobby. She is a facilitator of changelings and hags, often appearing in mortal guise to befriend changelings and slowly gaslight them into accepting their haggish nature. Although she may reunite changelings with their hag mothers, she is just as willing to unite unrelated hags. Auntie Splitfoot has joined several covens as a part time member, especially in order to help them recruit changelings, before moving on. Auntie Splitfoot often kills changelings who refuse to embrace their haggish nature, and their souls make up a significant minority of the ones she sells to the Lower Planes.

Auntie Splitfoot CR 11 XP 12,800 Advanced mutant night hag NE Medium aberration (augmented outsider, evil, extraplanar) Init +5; Senses darkvision 60 ft.; Perception +17 Defense AC 32, touch 15, flat-footed 27 (+5 Dex, +13 natural, +4 armor) hp 122 (8d10+80); fast healing 5 Fort +18, Ref +9, Will +12 DR 10/cold iron and magic; Immune charm, cold, fear, fire, sleep; SR 26 Offense Speed 20 ft., fly 30 ft. (good maneuverability) Melee 2 claws +17 (1d4+9), bite +17 (3d6+9 plus disease) Ranged +1 adaptive composite longbow +14/+9 (1d8+10/x3) Special Attacks dream haunting Spell-Like Abilities CL 8th, concentration +13 Constant—detect chaos, detect evil, detect good, detect law, detect magic At will—deep slumber (DC 18), invisibility, magic missile, mirror image, ray of enfeeblement (DC 16) At will (with heartstone)—etherealness, soul bind Statistics Str 29, Dex 21, Con 30, Int 22, Wis 18, Cha 21 Base Atk +8; CMB +17; CMD 32 Feats Alertness, Deceitful, Improved Natural Weapon (bite), Power Attack Skills Appraise +14, Bluff +18, Diplomacy +13, Disguise +18, Fly +17, Intimidate +16, Knowledge (arcana) +14, Knowledge (planes) +17, Perception +17, Sense Motive +17, Spellcraft +17, Use Magic Device +13 Languages Abyssal, Aklo, Celestial, Common, Daemonic, Infernal Gear +1 adaptive composite longbow, 20 adamantine arrows, 40 arrows, handy haversack, heartstone, 298 gp SQ change shape (any humanoid, alter self), deformities (lame, misshapen), heartstone, mutations (fast healing, flight, mental armor, spell-like ability) Special Abilities Disease (Su) Demon Fever: Bite—injury; save Fort DC 24; onset immediate; frequency 1/day; effect 1d6 Con damage (target must save a 2nd time or 1 point of the damage is drain instead); cure 2 consecutive saves. The save DC is Constitution-based. Dream Haunting (Su) A night hag can visit the dreams of chaotic or evil targets by using a special periapt known as a heartstone to become ethereal, then hovering over the creature. Once it does so, it rides on the victim's back until dawn. The sleeper suffers tormenting dreams and takes 1 point of Constitution drain upon awakening. Only another ethereal being can stop these nocturnal intrusions by confronting and defeating the night hag. Heartstone (Su) All night hags carry a heartstone—a special gemstone worth at least 1,800 gp that is worn as a periapt. A heartstone's magic is fueled by the hag's spirit and proximity—once separated from its owner (or upon the hag's death), a heartstone retains its magic for only 24 hours before becoming a nonmagical gem again. The heartstone instantly cures any disease contracted by the holder. In addition, a heartstone provides a +2 resistance bonus on all saving throws (this bonus is included in the statistics block above). A night hag that loses this charm can no longer use etherealness or soul bind until it finds a replacement gemstone.

#auntie splitfoot#night hag#hag#monster girl summer#age of monsters#age of monsters spoilers#pathfinder 1e#mutant

37 notes

·

View notes

Text

Power Without Noise: The Elegant Intelligence Behind the DC-DC Converter

We live in a world powered by invisible rivers of energy. Whether it’s your phone charging on the desk, an EV gliding silently down the highway, or a satellite stabilizing its orbit above Earth, all of it depends on a quiet and tireless guardian: the DC-DC converter.

It doesn’t have a flashing screen or make mechanical sounds. But it’s doing something profound—transforming power with precision. If you’ve ever wondered how today’s electronics, vehicles, and machines stay so compact, efficient, and smart, the answer often lies in the humble DC-DC converter.

A Quiet Transformer in the Digital Age

Electricity isn’t always one-size-fits-all. Devices and systems require varying voltage levels, depending on the task. A processor might need 1.2V, a motor controller 12V, and a battery bank 48V. But if all you have is a 24V supply, how do you cater to such variety without loss?

This is where DC-DC converters come in. They regulate voltage from one DC level to another—efficiently and reliably.

But here’s the kicker: they’re not just voltage changers. They’re voltage sculptors. They take raw power and fine-tune it with intelligence, efficiency, and minimal heat loss.

DC to DC: What's the Real Deal?

To the non-engineer, a DC-DC converter may seem abstract. So let’s unpack it in simple terms:

Step-down converters (buck) lower the input voltage to power sensitive electronics.

Step-up converters (boost) raise low voltages—useful in things like portable solar power banks.

Buck-boost converters can do both, ideal in systems where voltage fluctuates unpredictably.

They’re made of inductors, capacitors, switches (often transistors), and controllers. The switching mechanism rapidly turns power on and off—so fast that your devices never feel the pulses. Instead, they receive a steady, safe, and clean voltage.

Think of it as a dance—precision, timing, and flow—except it happens millions of times per second.

The Real-World Importance

Let’s get practical. Say you're designing a drone. You’ve got a Li-ion battery that outputs 14.8V, but your motor controller needs 12V and your GPS module 5V. With space and weight at a premium, you need compact, efficient power conversion.

Enter a compact, multi-output DC-DC converter.

In the automotive world, DC-DC converters play a massive role. Modern electric vehicles often have high-voltage batteries (400–800V) but still require 12V to run legacy systems like lights, wipers, and infotainment. A DC-DC converter bridges that gap—quietly ensuring every component gets what it needs.

And in space tech? Satellites must operate efficiently with constrained solar energy. There's no room for waste. That’s why aerospace engineers obsess over high-efficiency DC-DC converters with radiation-hardened designs. They might not make headlines, but they keep the mission alive.

Efficiency Isn’t Optional—It’s Mission-Critical

Every watt lost in conversion equals:

Heat that needs to be dissipated

Power that must be generated (and paid for)

Batteries that deplete faster

Components that wear down sooner

Today’s converters boast efficiencies of 95% or more. That means less heat, longer life, and smaller form factors. And in battery-powered systems, that efficiency can directly translate into hours more runtime.

In data centers, for example, thousands of servers depend on high-density power supplies with integrated DC-DC converters. A 1% efficiency improvement could save hundreds of thousands of dollars annually in energy and cooling costs.

Innovation: From Bulky to Ultra-Compact

Just a decade ago, power supplies were bulky and heavy. But with advances in GaN (Gallium Nitride) and SiC (Silicon Carbide) semiconductor technologies, DC-DC converters are shrinking rapidly while delivering more power.

These new-age materials switch faster, generate less heat, and allow higher-frequency operation—meaning smaller inductors and capacitors. The result? A converter that fits in your smartwatch yet handles power like a champ.

And it’s not just about size. It’s also about control.

Modern converters come with digital interfaces—PMBus, I²C, or UART—so system designers can monitor voltage, temperature, and current in real time. Smart converters are no longer passive hardware—they’re programmable, adaptive, and data-rich.

Let’s Talk Human: Why Should You Care?

You might not be designing a rocket or an EV. But chances are, if you’re in product design, industrial automation, or even IT infrastructure, you’ve already faced the challenge of powering diverse systems cleanly and safely.

A poorly chosen or inefficient DC-DC converter might lead to:

Device overheating

Unexpected shutdowns

EMI issues that interfere with wireless signals

Reduced lifespan for expensive components

On the flip side, a thoughtfully integrated converter means:

Smaller PCBs

Cooler operations

Lower energy bills

Happier end-users

In essence, choosing the right DC-DC converter is a high-leverage engineering decision—quietly influencing performance, reliability, and customer satisfaction.

Application Spotlight: Solar + Storage

Let’s take a green energy example. A solar-powered off-grid system might generate power in DC—say 18V from panels—but store it in 12V batteries and run devices at 5V USB or 24V for a water pump.

Here, multiple DC-DC converters orchestrate this energy symphony:

MPPT charge controllers use buck or buck-boost converters

Inverters depend on steady DC input for efficient AC output

USB charging hubs rely on precision 5V outputs

And if these converters weren’t efficient, the whole premise of “green” would start to crack.

The Future Is Smart, Modular, and Even Smaller

Looking ahead, the world is moving toward distributed, modular power systems. Imagine every module—whether it’s a sensor, a display, or a motor—having its own mini converter that adapts to the central supply.

The result? Simplified system design, better energy use, and easier scaling.

This modular vision is being realized in 5G base stations, autonomous robots, and edge computing nodes. The unsung hero behind it all? You guessed it—the DC-DC converter.

Final Thought: Honor the Invisible Genius

In a world that celebrates sleek screens, shiny finishes, and user interfaces, it’s easy to forget the underlying intelligence that makes it all possible.

But engineers know. Designers know. And now—you know.

So the next time you see a high-performing, ultra-thin, cool-running device, think about what’s inside. Somewhere behind that flawless function is a compact, efficient DC-DC converter quietly doing its job, a guardian of clean power in a chaotic electrical world.

0 notes

Text

I was tagged by @counterwiddershins for these ask game, in the spirit of getting to know someone better or just checking in on them. So!

Favorite color: Green, most shades, but especially the ones with blue undertones. Also berry purple, cinnamon browns, shades of cream. These colors, along with black and navy, make up the basis of my fall wardrobe, which (due to my job as a cemetery admin) indulges my inner wannabe-goth (alas, I am Enid, not Wednesday) and my 1930s vintage vibes, which look I am calling Librarian Noir.

Last song: AC/DC "Thunderstruck" and Beethoven's Ninth. Ask me about the similarities; I dare you.

Last movie: "A Haunting in Venice". I haven't quite enjoyed Branagh's Poirot films, so I wasn't sure about it going in, but it was wonderfully spooky, with superb storytelling, an excellent score, wonderful costumes, and exactly the kind of atmosphere I want in a mystery where the ghosts, real or imagined, are active characters.

Currently watching: "Only Murders in the Building", which I adore. I want to live in the Arconia and be friends with all of them. It's a warm hug kind of a show.

Other stuff I watched this year: NCIS New Orleans. I, uh, dropped my basket kind of hard this summer and needed something to take my mind off it all, so I watched all seven seasons' worth of episodes in two months. I have no regrets.

Shows I dropped this year: I don't actually tend to watch a lot of tv. I either binge something in its entirety or don't bother at all.

Currently reading: I am between books and trying to decide whether to go with a mystery called "Very Wong's Unsolicited Advice for Murderers", which could be great or could be awful, and P.G. Wodehouse's "The Inimitable Jeeves". This is where I sheepishly admit that my youthful Wodehouse's did not include the Jeeves and Wooster stories, which lack I am rectifying.

Tagging: @accidentallylita, @belphegor1982, @picklebrinedgoblinmind, @owlsongsandgoblinlaughs, and anyone else who would like to participate!

12 notes

·

View notes

Text

What is a DC Load Bank Used For?

Unmasking the Powerhouse Behind Your Devices

In the bustling world of electricity, where power generation, transmission, and distribution are the lifeblood of modern living, there exists a lesser-known yet indispensable component: the DC load bank. While it might not be a household name, its role in ensuring the reliability and efficiency of power systems is paramount. Let’s dive into the world of DC load banks and uncover their significance.

What Exactly is a DC Load Bank?

Think of a DC load bank as a diligent workout buddy for your power sources. It’s essentially a device engineered to simulate electrical loads for direct current (DC) power sources. Composed of resistive elements that transform electrical energy into heat, it effectively draws power from the system under test. While this might sound simple, its applications are vast and crucial.

Why Do We Need DC Load Banks?

The primary purpose of a DC load bank is to assess and evaluate the performance of DC power sources. This includes:

Battery Testing: Batteries are the heart of numerous DC systems, from electric vehicles to uninterruptible power supplies (UPS). Regular testing is crucial to ensure they can deliver the required power when needed. DC load banks mimic real-world conditions, allowing for precise evaluation of battery capacity, discharge rate, and overall health.

UPS Testing: UPS systems provide backup power during outages. Load banks simulate heavy loads, mirroring real-world scenarios and helping determine if the UPS can handle the demand.

Generator Testing: Even though generators primarily produce AC power, they often have DC systems for control and excitation. DC load banks can be used to test these components.

Rectifier Testing: Rectifiers convert AC to DC power. Load banks aid in evaluating their performance and efficiency.

Research and Development: In laboratories and research facilities, DC load banks are used to test new battery technologies, power electronics, and other DC systems.

Real-World Applications

To grasp the importance of DC load banks better, let’s explore some real-world examples:

Data Centers: Data centers heavily rely on UPS systems to shield critical IT equipment from power outages. Regular load testing using DC load banks is crucial to ensure the UPS can handle the load and prevent costly downtime.

Renewable Energy: Solar and wind power systems often incorporate battery storage. Load banks are used to test the performance and capacity of these batteries.

Electric Vehicles: Battery electric vehicles (EVs) are gaining popularity. Manufacturers employ DC load banks to test the performance and longevity of EV batteries under various conditions.

Military and Aerospace: In these sectors, reliable power is paramount. DC load banks are used to test batteries, power supplies, and other DC equipment in harsh environments.

EMAX Load Bank: A Powerhouse Solution

EMAX Load Bank specializes in providing top-tier DC load bank solutions. With a commitment to quality and innovation, EMAX offers a range of load banks tailored to meet diverse industry needs. From compact units for research to heavy-duty solutions for industrial applications, EMAX has you covered.

youtube

Benefits of Using DC Load Banks

Enhanced Reliability: Regular testing with a DC load bank helps identify potential issues before they lead to system failures.

Increased Efficiency: By accurately assessing power system performance, load banks help optimize energy usage.

Extended Equipment Lifespan: Proper maintenance, enabled by load bank testing, can prolong the life of batteries and other components.

Compliance: Many industries have regulations requiring regular testing of power systems. DC load banks help ensure compliance.

Cost Savings: Preventing unexpected failures and maximizing equipment lifespan can result in significant cost savings.

Conclusion

DC load banks, though often overlooked, are the unsung heroes of power systems. By simulating real-world conditions, they provide invaluable data for testing, troubleshooting, and optimizing performance. As our reliance on DC power continues to grow, the importance of load banks will only increase.

2 notes

·

View notes

Text

That's a full wave bridge rectifier. It's a (now somewhat outdated in most applications) method of getting a steady DC (or DC-ish) current from an alternating current. The transformer to the left of the diagram (basically two big coils of wire with a specific number of loops relative to each other) gets used to step an AC voltage up or down to a peak voltage a little above the final desired DC voltage. Then the diode circuit on the right has the effect of letting the positive part of the wave through and inverting the negative part of the AC sine wave.

Paired with a capacitor and a voltage regulator, you can get a pretty clean DC voltage out the other side with a well-designed rectifier.

But we tend to use a more modern circuit design now, which doesn't require the big, bulky transformers used in linear power supply circuits like the above. The new ones still need a transformer, but it can be much smaller. That's why phone chargers and other chargers got so much smaller and lighter recently — there's just a lot less copper wire inside.

And not to burst any bubbles, but in practice, rectifier circuits aren't physically laid out like the diagrams. Here's one, with the capacitor, but without the transformer component. That would get hooked up to two of the screw terminals, and the other two are the DC output.

i unironically believe electricity is the closest thing we have to magic in this universe. consider:

it's basically what human "souls" are made of (your consciousness is the result of miniscule amounts of electric charge jumping between neurons in your brain)

when handled incorrectly or encountered in the wild, it is a deadly force that can kill you in at least half a dozen different ways

when treated respectfully and channeled into the proper conduits, it is a power source that forms the backbone of modern society

if you engrave the right sigils into a rock and channel electricity into it, you can make the rock think

there is a dedicated caste of mages (electrical engineers) tasked with researching it in ivory towers

whatever the fuck Galvani was doing with those frog legs

look at this and just try to tell me it isn't a kind of summoning circle

52K notes

·

View notes

Text

research tips for electric train whump:

-INDUSTRIAL MAINTENANCE SOURCES ARE YOUR FRIEND! There’s not much stuff specifically about trains but basic concepts (maintenance and repair of AC or DC motors, transformers, rectifiers, other heavy electrical equipment) largely carry over from sources about elevators or substations. There’s a lot of good videos on youtube about these topics, look into stuff aimed at apprentice electricians or industrial maintenance, it will generally be more visual/metaphor and less math-heavy if you struggle with that.

-many “breakdowns” are actually due to power infrastructure issues- third rail and catenary wires have different problems and these further vary based on how old they are. Fixed-tension catenaries on the former Pennsylvania Railroad are a notorious issue. The more modern the line, the less weird stuff you’ll have, but much of the US, parts of the UK, and a number of spots in mainland Europe have more unusual and antiquated electrification systems. And this is also an issue with model trains between brands and eras!

-On a related note, pantograph designs have varied by time and place and have different advantages/disadvantages/issues. You even have times when they have a uniquely bad time with old catenaries, like old Comet EMUs specifically getting snarled in those constant-tension PRR catenaries

-Never underestimate how “dumb” and un-computery a lot of electric trains actually are, especially circa the 80s. “Toaster” isn’t even an inaccurate insult for older DC-motor trains, they literally brake using huge resistors that put out a ton of heat… like a giant toaster. And the really old, simple stuff tended to last a stupidly long time in service so you can 1000% wave off a 20s-era engine or EMU in the 80s.

-If you want some really easy ones that have actually happened before: connecting to too strong of a power source and getting FRIED, and having wires ripped out willy-nilly by techs not familiar with electric trains that don’t know what they’re doing. Weaponized incompetence with anything electrical checks out with how even a lot of train people know very little about it and don’t care.

-model trains also have a lot of beginner-friendly electrical info you can work from

#stex#starlight express#a lot of this stuff also applies to diesel-electric engines (which is almost all diesels)#they just have an engine as a generator vs connecting to an external power source#older electric locomotives will have a lot more in common with appliances or factory machinery than computers#rail is generally technologically conservative since it’s VERY heavy duty and high reliability and likes to reuse vs replace#it’s actually really handy to know the basic electrical stuff that goes into them because it’s applicable to tons of everyday stuff

23 notes

·

View notes

Text

Demand-side response is an integral part of the modern, flexible energy system evolving in the India today. Costa Power works in the feild of online ups suppliers in India with a multitude of financial benefits to business by reducing energy bills, and providing revenue streams. From a long-term point of view, demand-side response will help to reduce carbon emissions, supporting responsible business practice and protecting the environment. CPIPL provides solution to enhance the security of our electricity supply – reducing the potential for disruptive power outages and price hikes that we all want to avoid. Costa power covers and engaged in all possible solution as online ups battery suppliers i.e online ups dealers in mumbai, online ups suppliers in mumbai, ups amc services in mumbai as well as in India along with small cities, Industrial online ups suppliers and system integration, Luminous online ups dealers in mumbai, Microtek online ups suppliers in mumbai for home and industry use which are very critical now a days. All that said, much more work needs to be done when it comes to reassuring mission critical businesses that the use of emergency Online ups dealers in Mumbai in a demand response capacity can be achieved in a risk-free manner.

Costa Power have established excellent relationship with our clients as online ups suppliers, online ups battery consultants and online ups battery vendors at pan India level.

Costa Power, online ups suppliers in India from 1kVA online ups to 300kVA online ups up to 8 units in parallel operation galvanic isolation at output line with the protect of latest technology of international brand you will benefit from a robust and easy to operate UPS meeting the relevant EMC and other international standards. It can be custom-designed online ups battery manufacturers in India for use in harsh industrial environments. With an expected lifetime of at least 20 years, the Protect 8 is a robust and cost-effective online ups battery solution optimized for minimal operating costs.

Costa Power designed to meet the toughest product customization, requirements for specific mechanical protection degree, input & output voltage, battery and autonomy times and comes with the desired documentation. Benefit from a guaranteed short lead time, extremely high electrical and mechanical robustness, high reliability and a small footprint. And with its own personnel the following services:

Costa Power design solution as online ups suppliers of a capacity of up to 600 kVA Online ups, ensuring the safe operation of your critical loads. By this designed to meet the toughest application requirements and offers high reliability with efficient 12 pulse rectifier technology for sinusoidal input current and for reduced input current harmonic distortion

Industrial online ups manufacturers in India is the Modular online UPS systems that combines high AC/DC efficiency values with a compact footprint and a flexible and scalable architecture, able to reach up to 900 kVA. The combination of high-level performance, of online ups in India with integrated online ups battery solutions, or inbuilt galvanic isolation, the compact footprint and the wide range of options, make industrial online UPS the best solution for the power quality of any critical load.

The level of proximity industrial online ups manufacturers is a Online UPS battery systems with a high operating AC/DC efficiency and compact footprint. The 3 phase online ups is based on a 2U high 10kVA/kW power module, providing up to 40 kVA maximum capacity or 30 kVA N+1 configurations. three phase online ups in Mumbai is a online UPS battery system with a high operating AC/DC efficiency and compact footprint.

#Upsbattery#Upsbatterydealers#Upsbatterydistributor#Upsbatterysuppliers#Upsamc#Upsapc#Microtekinverter#Quatabattery#Luminousups#Emersonups#Onlineups#Digitalups#Offlineups#Bestups#Bestbattery#Servostabilizer#Vertivups#Exidebattery#Luminousinverter#Upsdealers#Upssuppliers#Upsdistributors

0 notes

Text

Understanding Generator Excitation Systems: A Complete Beginner’s Guide

When it comes to power generation, understanding how the system works behind the scenes is key—especially when it involves the generator excitation process. This essential component plays a pivotal role in controlling voltage and ensuring a stable supply of electricity. Whether you're just entering the field of electrical engineering or simply curious about how generators keep your lights on, this beginner-friendly guide will walk you through everything you need to know.

What Is Generator Excitation?

In simple terms, generator excitation refers to the process of supplying direct current (DC) to the rotor winding of a generator. This creates a magnetic field that is necessary for generating electricity. Without excitation, the generator cannot produce the required electromagnetic field, and thus, no electricity can be generated.

Why Is Excitation Important in Power Generation?

Excitation controls the generator’s output voltage. It helps maintain system stability, regulates power factor, and ensures reactive power support in electrical grids. In the U.S., where power grids are vast and highly interconnected, managing these parameters efficiently is critical to avoiding voltage fluctuations and potential blackouts.

Types of Generator Excitation Systems

There are mainly two categories of generator excitation systems:

Static Excitation Systems These use external power sources like an exciter transformer and rectifier to supply DC to the rotor. Static systems are fast, precise, and often used in large-scale power plants.

Brushless Excitation Systems In this type, the exciter is mounted on the same shaft as the generator. It eliminates the need for brushes and slip rings, reducing maintenance and improving reliability. Many utility-scale generators across the U.S. use brushless systems due to their durability.

How the Excitation Process Works

The excitation system supplies current to the generator’s rotor winding. As the rotor turns inside the stator, its magnetic field induces a voltage across the stator windings. This induced voltage becomes the output of the generator. The more current supplied to the rotor (through excitation), the stronger the magnetic field and the higher the generated voltage.

Automatic Voltage Regulators (AVRs) monitor and adjust this excitation current in real time, ensuring consistent voltage regardless of load changes.

Components of a Generator Excitation System

A standard generator excitation setup typically includes:

Exciter (either brushless or static)

Automatic Voltage Regulator (AVR)

Rectifier (for converting AC to DC)

Control Panel (for monitoring and manual adjustments)

These elements work together to ensure optimal generator performance under varying conditions.

Benefits of a Reliable Excitation System

A well-maintained generator excitation system offers several benefits:

Stable Voltage Output: Maintains consistent power supply across varying loads.

Improved Grid Support: Balances reactive power for stable grid operations.

Enhanced Safety: Reduces the risk of electrical surges or generator failure.

Lower Maintenance: Especially in brushless systems where mechanical wear is minimized.

These advantages make excitation systems an indispensable part of generator operations in the U.S. power infrastructure.

Common Challenges and Troubleshooting Tips

Even robust systems face issues like:

Voltage Instability: Often caused by malfunctioning AVRs or faulty sensors.

Overexcitation or Underexcitation: Can result from incorrect settings or failing components.

Excessive Heat: Usually a symptom of electrical resistance or damaged wiring.

Regular maintenance, including insulation checks and AVR calibration, helps prevent these problems and prolongs system life.

Applications in Real-World Settings

In the United States, generator excitation systems are used across multiple sectors—from power plants and data centers to hospitals and industrial manufacturing facilities. Any place where continuous, stable electricity is critical depends on these systems to keep operations running smoothly.

Final Thoughts

A deeper understanding of generator excitation reveals its crucial role in modern power generation. From managing voltage to stabilizing the grid, this system ensures that electricity is generated efficiently and safely. As the demand for reliable power grows in the U.S., so does the importance of mastering the fundamentals of generator technology. Whether you're an aspiring engineer or facility manager, knowing how excitation works is the first step toward greater electrical control and system reliability.

Contact Info

2500 State Highway 160, Warrior, AL 35180

Phone: 205-590-3505

Email

Map

https://maps.app.goo.gl/c7y7BLamTPvecBqWA

0 notes